Electronics Manufacturing Services

Electronics Manufacturing Services (EMS)

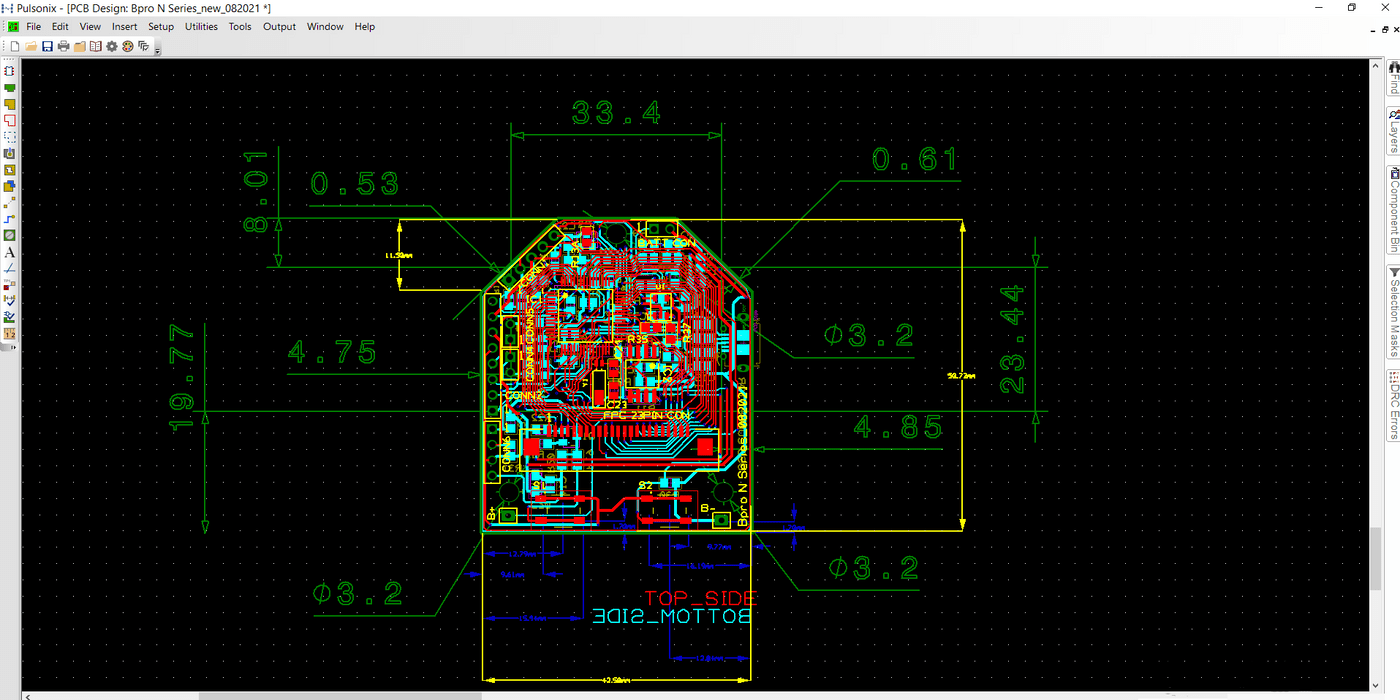

bpro has PCB design service activity which is carried out by a team of highly experienced professionals dedicated to customer services and interaction. We also undertake customized PCB design for various Form factors with very high mechanical constraints.

Services

PCB Design

Optimizing PCB layout design for manufacturability is one of the most crucial aspects of any product’s development process. Key decisions made during the design stage often have a tremendous impact on the cost and success of your product’s manufacturing and production.

Layers

Professional PCB Design Services of all types, including, Single-Layer, Double-Layer and Multi-Layer up to 12 Layers.

Layouts

Highly Complex & Dense PCB layout designs done with speed & accuracy

Services

Advanced component footprints & library creation including BGA, QFN packages as per IPC standards

Reverse Engineering

Reverse engineering services to correct flaws or to optimize existing PCB designs

Upgrade

Upgrade old PCB’s with outdated & obsolete components to the latest technology with widely available SMT components

Testing

Electrical & Functional Testing services of the designed PCB

We have experience with various PCB CAD tools with our primary tool being PULSONIX.

ELECTRONICS ASSEMBLY & MANUFACTURING

PCB Prototyping

PCB Testing

Wave Soldering

SMT Soldering

Manufacturing Machine We Use

SMT S10 YAMAHA PICK AND PLACE MACHINE

Board size : (with buffer unused) Min. L 50 x W 30 mm to

Max. L 1,330 x W 510 mm

Board thickness: 0.4 – 4.8 mm

Placement speed : (12 heads + 2 theta)

Opt. Cond. : 0.08 sec/CHIP (45,000CPH)

Placement accuracy A (μ+3 ) : CHIP +/- 0.040 mm, IC +/- 0.025 mm

Placement angle: +/-180 degrees

Component height: Max. 30 mm *1

KONARK 145 RE FLOW OVEN

Maximum PCB Width : 300 mm

Heating Length : 1550 mm

Max Temperature : 300˚C

Maximum Conveyor Speed : 2 m/min / 200 CPM

Clearance above Mesh : 60 mm

EMST PLCTT Wave Soldering

Overall dimensions : L – 1730 mm, W – 880 mm, H – 825 mm

Weight : 200 kg. (441 lb) max weight, without solder alloy

Supply voltage : Standard – 415 V, 3 phase, 50 Hz

Power consumption : 5 kVA total max

SEMI AUTO SCREEN PRINTER

Pcb size : 400 mm x 250 mm

Printing table size : 500 mm x 300 mm

Stencil size : adj. Up to 22” x 22”

Squeeze speed : 0-100 mm/sec

Power : 220v/ 50hz,

Pneumatic : 3cfm @ 5-7kg/cm 2