Manufacturing

What We Manufacturing

3D Printing

Injection Molding

PCB Fabrication

Blow Molding

Plastic Ultrasonics Welding

Compression Molding

CNC Machining

Sheet Metal Fabrication

3D Printing and Facility

3D Printing is a process for making a physical object from a three-dimensional digital model, typically by laying down many successive thin layers of a material. It brings a digital object (its CAD representation) into its physical form by adding layer by layer of materials.

Additive manufacturing has become more than an efficient prototyping technique: it is now a real manufacturing tool for your series and finished products, helping companies to overcome the constraints of traditional manufacturing.

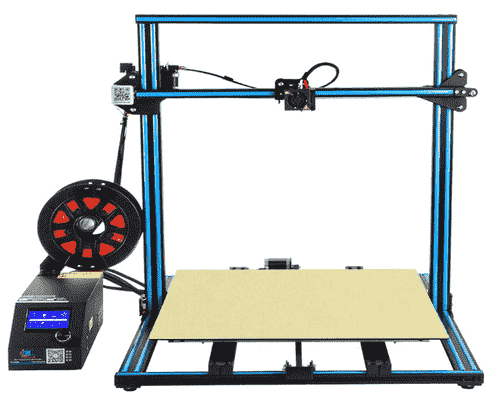

We are having stratasys polyjet and FDM type 3D printer and also service in metal type 3D printer. The polyjet type materials are,

Tango (Rubberlike)

Rigur and Durus (Polypropylene-Like)

Vero clear (Transparent)

Vero Family (Rigid)

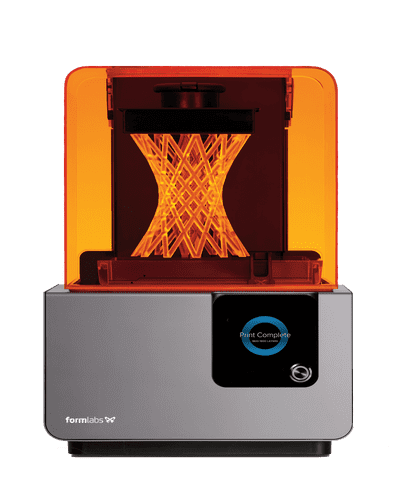

Model

Form 3

Technology

Printing Size

Printing Size

1.75mm

- Rigid Opaque: VeroWhitePlus™, VeroBlackPlus™, VeroGray™, VeroBlue™

- Rubber-like: TangoPlusTM, TangoBlackPlus™, TangoBlack™, TangoGray™

- Transparent: VeroClear™ and RGD720

- Simulated Polypropylene: Rigur™ and Durus™

- High Temperature

- Bio-compatible

- Works with SUP705 or SUP707

- Works with SUP705

PLASTIC INJECTION MOLDING

STM BRAND D130/I 510 Automatic Microprocessor Controlled Plastic Injection Molding Machine. Our injection molding is equipped with a variety of modern high precision conventional injection molding machines in the 130Ton. All molded products are processed using reliable molding principles with the best experienced operators, ensuring the best quality possible.

Injection molding machines are pre-programmed for production, the actual molding process is rapid compared to other methods of molding. Plastic injection molding process hardly takes times and this allows more parts to be manufactured from a single mold. The high production output rate makes plastic injection molding more cost-effective and efficient.

The following materials available for injection molding are,

• Poly propylene (PP)

• High Density Polyethylene (HDPE)

• High Impact Poly styrene (HIPS)

• Poly carbonate (PC)

• Blend of PC and ABS (PC/ABS)

Flow Chart

Our Strength