Tool Development

Tool Development

Our mold making department is capable of constructing and repairing numerous types of injection molds. plastic industries have significant experience in most modern mold construction systems and are fully capable of handling total construction testing and final production with ease, We are well experienced in dealing with.

Plastic Injection Mold

Medical product Mold

Electronic Enclosure Mold

Three Plate Mold

Two Plate Mold

Stripper Ejection Mold

Blow Mould

Ultrasonic Horn & fixtures

Rubber Mold

Hand Mold

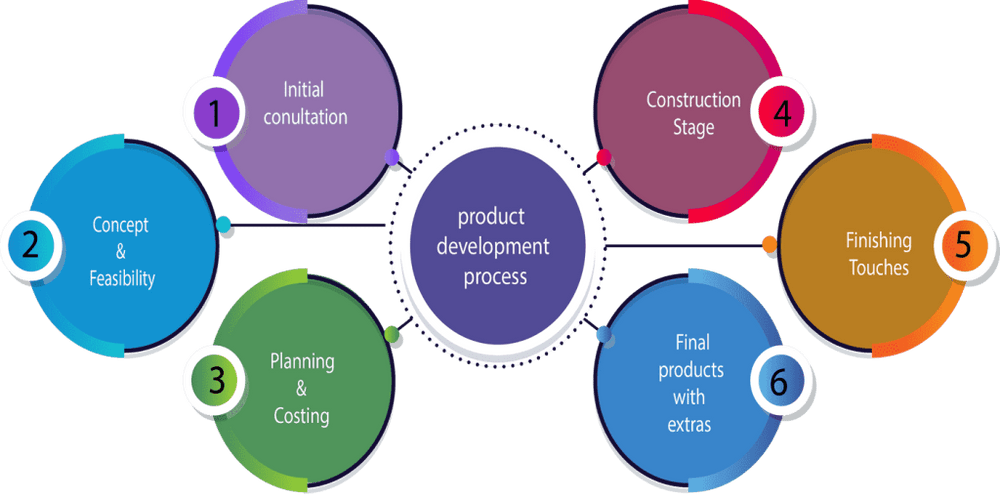

Product Development Process

The 6-Step Process:

1 Initial Consultation

Bpro Labs can assist you with the initial stages of designing the components that meet your needs. To have a better idea of what the final product will look like, 3D modeling is performed as an assembly of various parts. In order to select the right grade of material for your application, we have ties with various engineering plastic raw material manufacturers.

2 Concept & Feasibility

By using the 3D model, you can get a good idea of what the end product will look like. bpro labs can then determine whether the component is feasible for plastic mold design and manufacturing. As soon as the product is designed, we will support you until it is manufactured commercially

3 Planning & Costing

Bpro Labs can estimate the cost of producing the components once mold feasibility has been confirmed. Bpro Labs can produce your requirement cost-effectively by choosing the right machine from our existing range.

4 Construction Stage

As a mold designer, Bpro Labs can create the molds that are necessary to manufacture the components. It is estimated that a well-maintained mold can give a life of between a half and 1 million shots. A mold’s life is also determined by the raw material considered.

5 Finishing Touches

Bpro Labs produces parts that can be used directly without requiring any post-processing. In addition to meeting end-user requirements, critical parts avoid secondary operations post-molding, which would be costly in the long run.

6 Final products with extras

You can order the parts you need from bpro labs with the following:

a) – Screen Printing

b) – Pad Printing

c) – Ultrasonic welded parts